WESF plays a role in promoting standardization and eliminating global trade barriers.

New research by the National Institute of Standards and Technology (NIST) has uncovered an unexpected side effect of air sterilization devices: while designed to purify indoor air, certain cleaners may generate harmful chemical by-products in the process.

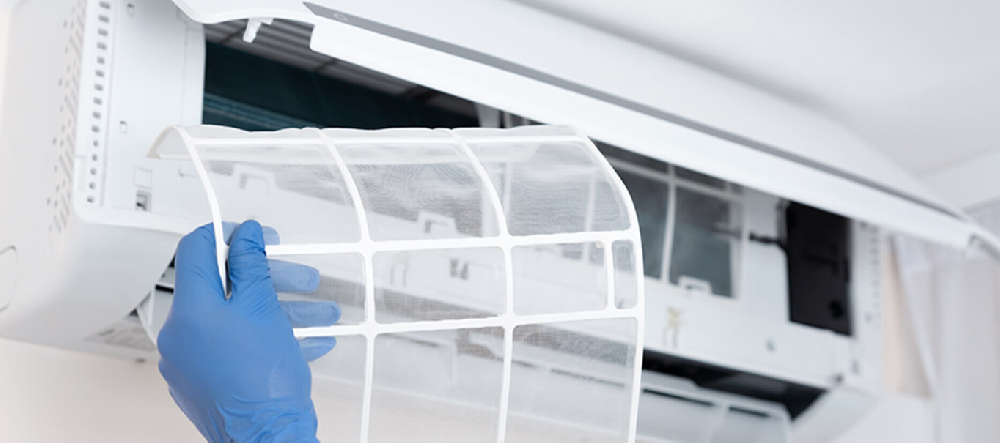

Air cleaners and HVAC filters are designed to filter pollutants or contaminants out of the air that passes through them. Air cleaning and filtration can help reduce airborne contaminants, which also include particles containing viruses, such as COVID-19. The pandemic, combined with increasingly severe wildfire seasons, has dramatically increased both consumer demand for air cleaning systems and industry production to meet these urgent public health needs.

As NIST reported, some air cleaning methods include shining ultraviolet (UV) light through room air, ionizing the air with electricity, or passing the air over catalysts that will react with pollutants and break them down into less harmful substances like water and carbon dioxide. However, some of these filtration processes can add new chemicals of their own: for example, UV light can create ozone, which is dangerous in high concentrations.

ANSI Member Efforts for Cleaner Air Environments

To mitigate the issue, NIST led the development of a new standard test method published by ASTM International that lays out a consistent way to measure and compare a wide range of air cleaner by-products: ASTM D8625, Standard Test Method for Chemical Assessment of Air Cleaning Technologies. The process involves running air cleaners for four hours in a sealed room containing specific chemicals. Researchers can analyze air samples for three key pollutants: ozone, formaldehyde, and ultrafine particles. They measure ozone and formaldehyde by passing UV light through the samples and detecting how much light gets absorbed. For ultrafine particles, they use scanning mobility particle sizing to assess the number of ultrafine particles that were in a given sample.

The standard also helps manufacturers make “improvements in their devices, enable consumers to make apples-to-apples comparisons, and pave the way for emission limits of these by-products.”

This standard is part of broader industry efforts to improve air quality. Other air filtration standards developed by ANSI members address a wide range of indoor or enclosed environments, including:

Homes: AHRI 681-SI, Performance Rating of Residential Air Filter Equipment, developed by AHRI

Enclosed Work Vehicles: SAE J 3078-2, Off-Road Self-Propelled Work Machines Operator Enclosure Environment - Part 2: Air Filter Element Test Method, developed by SAE International

Commercial and Industrial Facilities: ANSI/AHRI 851-SI, Performance Rating of Commercial and Industrial Air Filter Equipment, developed by AHRI

Further guidance documents developed by the U.S. standardization community include “Design Guidance for Education Facilities: Prioritization for Advanced Indoor Air Quality,” developed by ASHRAE, and “Use of Do-It-Yourself Filtration Devices During Wildfires,” developed by UL Standards & Engagement (ULSE). Partnering with international stakeholders, ASHRAE signed a Memorandum of Understanding in 2024 with the World Filtration Institute to enhance the built environment by championing energy efficiency, decarbonization, resilience, and improved indoor air quality.